07/10/2024

07/10/2024

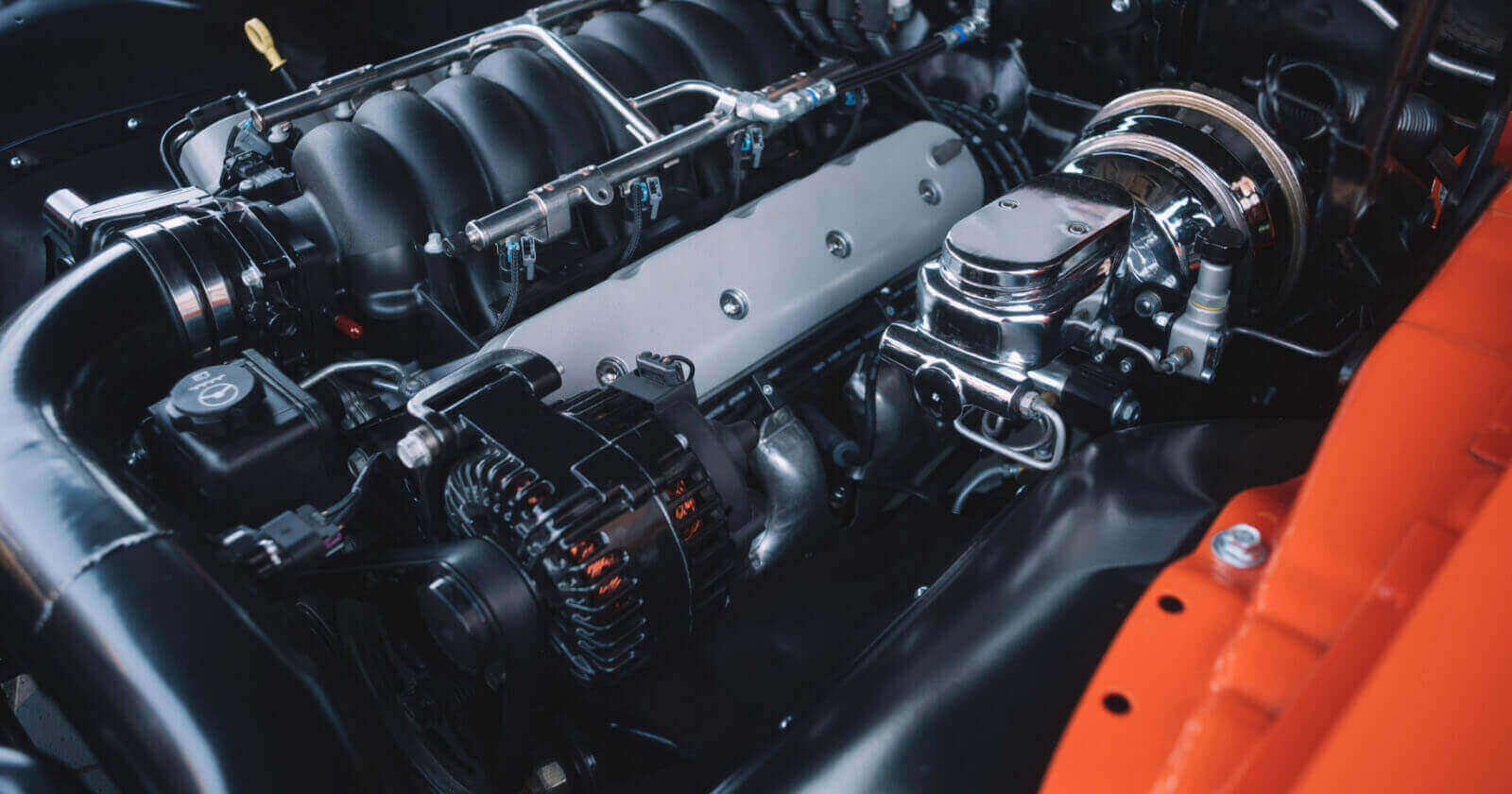

Engine maintenance is critical to ensuring the longevity and reliability of machinery, whether in automotive, industrial, or marine applications. With engines being the heart of most mechanical systems, regular maintenance practices can prevent costly breakdowns and extend the life of the equipment. This guide provides a detailed look at the best practices for maintaining various types of engines, focusing on preventive measures that every operator should know.

The first step in engine maintenance is understanding the specific needs of your engine type. Diesel engines, for example, require different care compared to gasoline engines. Regular oil changes, air filter replacements, and cooling system checks are essential for both types, but diesel engines often need additional care in areas like fuel injection systems and turbochargers. Ensuring that these components are clean and functioning optimally can prevent major issues down the line.

Another crucial aspect of engine maintenance is monitoring the health of the engine’s fluids. Over time, oil, coolant, and transmission fluids degrade and become less effective. Regularly checking and replacing these fluids can prevent overheating, excessive wear, and damage to internal components. This blog also delves into the importance of inspecting engine belts, hoses, and electrical systems, as these small components can cause major disruptions if neglected.

In this comprehensive guide, we also discuss common engine problems, such as overheating, knocking, and stalling, and how to troubleshoot them. By following a consistent maintenance schedule and understanding how to address minor issues before they become major repairs, businesses and individuals can significantly reduce downtime and repair costs.